Global B2B furniture procurement carries inherent risks. Delays, logistical errors, and quality defects on arrival are not mere possibilities; they are operational realities.

The true test of your supply chain is not the quote, but the resolution capacity. For operations managers and risk-averse procurement VPs, relying on a trading agent creates a structural gap in accountability. In contrast, partnering with a direct manufacturer is the only way to secure your project. A true production partner offers the ownership and control necessary to turn a potential disaster into a managed solution.

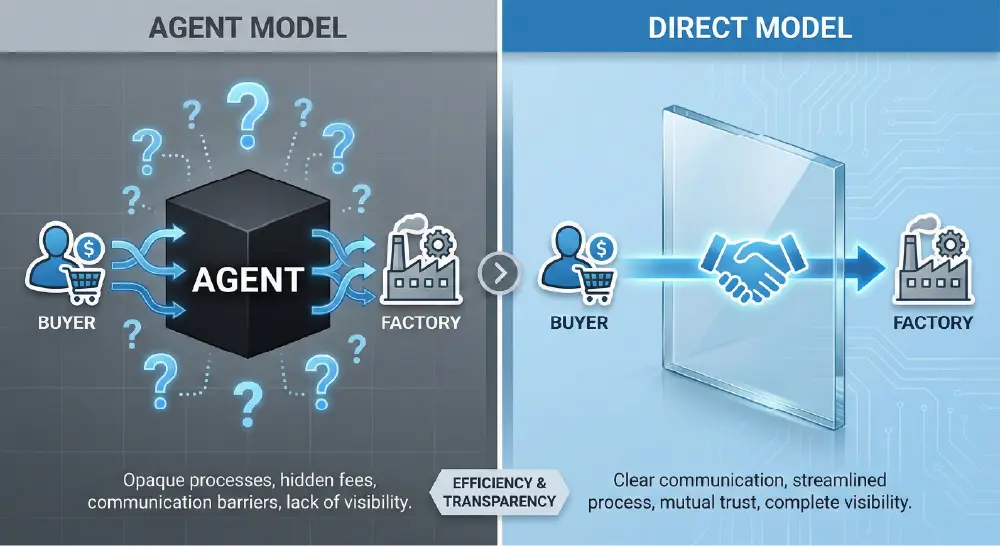

This article details how eliminating the intermediary to work with the source is the only way to gain full traceability and immediate problem-solving capacity.

1. The Resolution Deficit: Sales vs. Manufacturing

A trading agent’s core competency is sales, not manufacturing. When a crisis hits, the agent has no ownership over the production line. A direct manufacturer, however, owns the facility, the materials, and the schedule. This ownership allows the factory to resolve defects immediately.

Reliability depends on who owns the process:

- The Information Blockade: Agents control data. A direct partner provides transparent, real-time access to the factory floor, ensuring you are not blocked from the truth.

- The Refund Trap: Agents offer refunds. Manufacturers offer solutions. A production facility has the capacity to produce rapid replacements, whereas an agent can only offer financial compensation. This solution-oriented action is why going direct is superior to an intermediary, as detailed in supply chain expert analyses.

2. The Accountability Black Box: Visibility via Direct Partnership

The agent's business model relies on hiding the factory. This "Vendor Shielding" turns your supply chain into a black box. Working with a direct manufacturer eliminates this opacity.

The advantage in a crisis:

- Operational Speed: A direct relationship eliminates the lag time. When a defect is found, you speak to the technical team immediately, saving the 5-10 days typically lost to agent relays.

- Root Cause Analysis: Only a producer has the technical authority to diagnose a failure (e.g., moisture content vs. packaging). An agent guesses; a factory knows. This technical depth is a fundamental reason to choose a direct manufacturer, as identified in sourcing guides.

With a direct partner, accountability is absolute. You have access to the production manager and batch data, enabling immediate corrective action.

3. From Problem to Solution: The Manufacturing Approach

When a fault is identified, the remediation path highlights the difference between an agent and a producer:

The Agent’s Approach: Distancing

The agent minimizes liability. They cannot manufacture stock, so they delay. Without a direct relationship, disputes become protracted.

The Manufacturer’s Approach: Priority Rework

The factory owns the machine and the labor. They leverage this capacity to offer concrete solutions:

- Prioritized Production: Inserting replacement units into the next production slot.

- Technical Swaps: Allocating finished components from other orders to fix yours.

- Partnership Security: A manufacturer values the lifetime value of the account, focusing on resolution, not blame.

4. Operational Risk and Compliance: The Producer’s Role

Modern B2B sourcing requires strict adherence to standards. A direct manufacturer is your safeguard for compliance.

- The Compliance Gap: Agents forward papers. A partner verifies the process.

- The Direct Advantage: Working directly with the facility ensures access to verifiable legal documents (like SVLK). You can legally bind the producer to maintain certifications. This chain of custody is why direct sourcing is essential for ethical procurement. The importer is responsible for regulations, making the verification provided by a direct manufacturer vital according to global sourcing standards.

This control is precisely why a partner with integrated operations offers a superior product. See why an In-House Direct Manufacturer Wins.

If you are new to sourcing from a factory, knowing how to vet them is key. Read our list of Red Flags when choosing a Supplier.

5. Conclusion: Choose a Direct Manufacturer for Resilience

An agent creates distance. A partner creates security. This distance is a luxury you cannot afford.

The strategic choice to partner with a direct manufacturer is an investment in supply chain resilience. It swaps the defensive posture of an agent for the authoritative power of a production-based solution.

For a guide on navigating procurement with an Indonesian furniture manufacturer, read How to Buy from an Indonesian Direct Manufacturer.

When a crisis strikes, your choice of partner determines the outcome. Choose the partner who owns the solution.

Partner with Certainty: MPP Furniture is Your Direct Manufacturer

Eliminating the middleman requires a partner you can trust. At MPP Furniture, we are the Indonesian furniture supplier that bridges the gap between factory capacity and Western standards.

- True Direct Manufacturer: With over 20 years of experience, we manage the entire production cycle in-house.

- Traceability: We provide full SVLK certification.

- Crisis-Ready: Our "Grow Together" philosophy defines us as a partner that prioritizes your stability.

Stop renting your supply chain. Start owning it with a direct manufacturer.

Your next best-seller might be here

Request a quotation and custom options tailored to your needs today via WhatsApp or email.

Frequently Asked Questions

What are the risks of using a sourcing agent for furniture?

The primary risk involves a lack of accountability during a crisis. Because agents do not own the production facility, they cannot mandate rapid rework or replacement of defective goods, often resulting in extended project delays and limited financial compensation.

Why is a direct manufacturer better for crisis management?

A direct manufacturer owns the materials, labor, and machinery. This asset ownership allows them to immediately prioritize your rework, swap components from other production lines, and offer concrete technical solutions rather than just forwarding emails.

Who is liable for furniture compliance and customs issues?

The importer of record remains legally liable. If an agent provides outdated or fraudulent compliance documents, the importer faces the fines and customs holds. Partnering with a direct manufacturer allows for direct verification of legal chain-of-custody.

What is vendor shielding in supply chains?

Vendor shielding is a practice where trading agents hide the identity of the factory to prevent buyers from bypasssing them. This creates a "Black Box" supply chain, preventing the buyer from accessing root cause analysis or speaking to technical teams when quality issues arise.

I am a self-taught graphic designer with a deep passion for exploring the creative world through various tools and techniques. I have honed my skills in Adobe Illustrator, Photoshop, and Lightroom, while continuously expanding my knowledge by diving into After Effects and Premiere. Photography has become an integral part of my life, and I actively engage with it to capture moments and experiment with visual storytelling.

My fascination with color theory, histograms, and innovative design approaches drives my work, as I am always seeking new ways to push the boundaries of my creativity. From photography models and motion graphics to textures, collage, and surrealism, I am captivated by the endless possibilities in design and constantly strive to challenge myself with fresh and exciting ideas.

0 Comments