Many buyers encounter problems with Mindi wood furniture not at the factory, but weeks or months after the products arrive. Cracks, loose joints, or warped components often appear later, putting the buyer’s brand and customer trust at risk. In most cases, these failures are blamed on the material, even though the real issue lies elsewhere.

Based on our experience as an Indonesian furniture manufacturer, most defects in mindi furniture are not caused by the wood itself. They happen because Mindi is a process-sensitive material that requires strict control during drying, construction, and finishing. When suppliers take shortcuts or apply generic methods, defects become almost inevitable.

This article explains the common problems found in mindi wood furniture, the manufacturing causes behind them, and how buyers can prevent costly mistakes before placing bulk orders from Indonesia. The focus is not on defending Mindi Wood, but on helping you evaluate suppliers more safely and protect your business decisions.

Why Mindi Wood Furniture Develops Defects After Production and Shipping

Most defects in mindi wood furniture do not appear during factory inspection. They develop after the furniture goes through shipping, storage, and adjustment to a new climate. This delayed failure is the reason many buyers feel the problem comes out of nowhere.

Mindi wood is a fast-growing hardwood with good stability when processed correctly, but it reacts quickly to moisture imbalance. If different components within a single product have uneven moisture content, movement will occur after delivery. The furniture may look fine when it leaves the factory, but internal stress is already present.

We have seen this happen in real production. In one chair project, all components were straight during inspection, yet twisting appeared the next day. The root cause was not design, but improper wood preparation before kiln drying.

This is why many buyers mistakenly question the material itself, even though mindi wood can perform well for furniture when its basic properties are properly respected during manufacturing.

Common Defects Found in Mindi Wood Furniture

When mindi wood furniture fails, the visible problems are often treated as the main issue. Buyers report cracking panels, loose joints, or furniture that no longer sits straight. These defects are real, but they are only symptoms of deeper process problems that happened earlier in production.

Understanding these symptoms helps buyers avoid wrong conclusions. Instead of assuming mindi wood is weak or unsuitable, it becomes clear that the way the mindi furniture was processed plays a much bigger role. Based on our experience, the most common defects buyers encounter when sourcing mindi furniture in bulk are. When produced with the right controls, mindi furniture can still deliver a stable and reasonable lifespan for indoor use, even in commercial settings:

1. Cracking in Mindi Wood Furniture After Climate Change

Cracking appears after the furniture adjusts to a new environment. Changes in humidity between the factory, shipping container, and final destination cause the wood to release internal stress. When the moisture content (MC) is uneven, cracks often show up along panels, legs, or joint areas.

2. Broken Joinery in Chairs and Tables Made from Mindi Wood

Loose or broken joints are common complaints, especially for chairs and dining tables. This happens when joinery methods are not designed for Mindi wood’s density and movement behavior. Screws, nails, or weak joints may hold during inspection but fail after repeated use or minor wood movement.

3. Warping and Twisting Caused by Unstable Mindi Wood Components

Warping and twisting occur when different parts of the furniture move at different rates. Table tops may bend, chair legs may no longer align, or frames may twist slightly over time. These issues are often linked to improper drying or rushed preparation before production.

4. Inconsistent Quality Across Bulk Mindi Furniture Orders

Another frequent issue is inconsistency across one shipment. Samples may look solid, but products inside the container vary in stability and finish. This indicates uneven material preparation or a lack of standardization during bulk production, rather than a flaw in the mindi wood itself.

The Real Causes of Mindi Wood Furniture Problems at the Manufacturing Level

Most mindi wood furniture defects can be traced back to manufacturing decisions, not material limitations. At this stage, the problems usually start long before assembly begins. When an Indonesian furniture factory lacks proper systems and technical understanding, small shortcuts compound into visible failures later on.

The key issue is that Mindi Wood does not tolerate rushed or generic processing. It requires specific handling standards that many factories overlook, especially when production speed is prioritized over stability. From our experience, below are the main causes that consistently lead to defects in mindi furniture.

1. Moisture Content Issues in Mindi Wood During Kiln Drying

Moisture content control is one of the most critical factors in mindi furniture production. When Mindi Wood enters the kiln without proper pre-drying, moisture is removed too quickly from the surface while the core remains wet. This imbalance creates internal stress that later releases through cracking, warping, or twisting after delivery.

Consistent results require mindi wood to reach a moisture content below 12% gradually, not aggressively. Without this control, even furniture that looks stable during inspection is already carrying hidden risks.

2. Improper Joinery That Does Not Match Mindi Wood Characteristics

Many suppliers use the same joinery standards for mindi that they use for denser hardwoods. This approach ignores Mindi Wood’s lighter density and higher movement sensitivity. As a result, joints may hold initially but loosen over time as the wood responds to environmental changes.

Proper joinery for mindi furniture must account for movement, load distribution, and repeated use. When joinery design is treated as an afterthought, structural failures become unavoidable in real-world use.

3. Suppliers Without a Technical Understanding of Mindi Wood Behavior

The final and most overlooked cause is the supplier’s lack of technical understanding. Some manufacturers treat mindi wood as a generic alternative rather than a material with specific behavior. Decisions are based on habit or speed instead of performance.

When suppliers do not understand how Mindi reacts to moisture, climate change, and structural stress, quality becomes inconsistent. In these cases, defects are not accidents; they are predictable outcomes of insufficient process control.

How an Experienced Indonesian Furniture Manufacturer Prevents Mindi Wood Defects

Preventing defects in mindi wood furniture is not about one single technique. It requires a controlled system that starts before production and continues until bulk orders are completed. From our experience as an Indonesian furniture manufacturer, stability comes from discipline in the process, not speed.

Instead of relying on visual inspection alone, we focus on controlling the variables that usually cause failure after delivery. This is also why working with an Indonesian furniture supplier who understands mindi wood at the production level makes a significant difference in long-term performance. This includes how the wood is prepared, how the furniture is constructed, and how consistency is maintained across large quantities.

1. Maintaining Consistent Moisture Content Using Controlled Kiln Drying

We treat moisture control as a staged process, not a single step. Before kiln drying, mindi wood is dried gradually through controlled air or sun drying to release moisture evenly. Only after this stage does the wood enter the kiln, where the moisture content is brought down slowly to below 12%.

This approach reduces internal stress in the wood. As a result, the furniture remains stable not only during inspection, but also after shipping and climate adjustment in the destination market.

2. Tabletop Joinery Standards to Control Movement in Mindi Wood Furniture

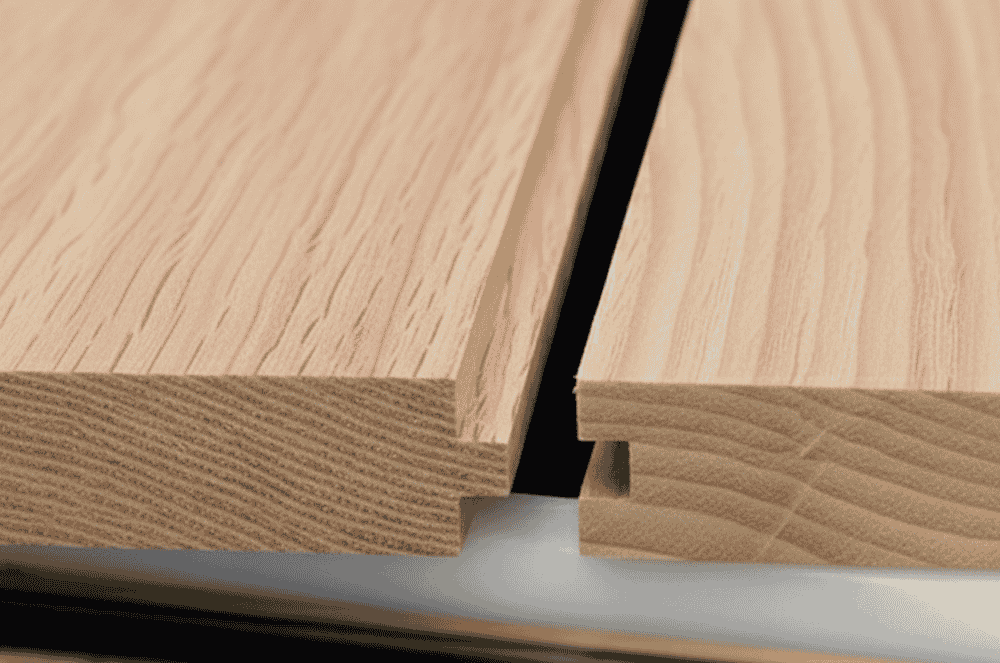

For tabletops and wide panels, wood movement is the primary risk. We prioritize quarter sawn mindi wood, where the grain stands more vertically, instead of flat sawn boards with sideways grain. This grain orientation provides better dimensional stability and reduces the chance of warping over time.

To manage natural movement, tabletops use tongue and groove joints combined with countersink screw support. This allows the wood to expand and contract without forcing stress into the panel. When required by design or load, dovetail joints are added to strengthen the structure without locking the wood unnaturally.

3. Chair and Table Leg Joinery for Long-Term Structural Strength

Chairs and table legs carry repeated loads and movement, so their joinery must focus on long-term strength rather than speed. Simple screw or nail connections are avoided because they loosen easily as mindi wood responds to daily use and humidity changes.

For these structural areas, we use mortise and tenon joints reinforced with dowel pins through the tenon. This construction increases joint strength and keeps the connection stable over time, even under repeated stress.

4. Locking Construction Systems at the Sample Stage Before Mass Production

All construction methods and joinery decisions are finalized during the sample development stage. We test which joints are the most stable, efficient, and suitable for bulk production before mass manufacturing begins.

This approach ensures the product performs well not only as a sample, but also when produced at scale. By defining the construction system early, we avoid production disruption and quality inconsistency, delivering furniture that remains reliable from the first item to the last container.

5. Applying Technical Knowledge Specific to Mindi Wood Furniture

Mindi Wood performs best when designs respect its characteristics. We avoid forcing it into constructions better suited for heavier hardwoods. Panel thickness, joint placement, and structural balance are adjusted to match how Mindi reacts to moisture and load.

This technical understanding allows Mindi Wood Furniture to perform reliably for its intended use. When the material is treated correctly, defects are not minimized by chance but prevented by design.

Mindi Wood Is Not the Problem; The Manufacturing Process Is

Most problems associated with mindi wood furniture are not caused by the material itself. They are the result of how the wood is prepared, dried, constructed, and standardized during production. When these steps are rushed or treated generically, defects become almost unavoidable, regardless of how good the raw material looks.

For buyers, this means sourcing mindi furniture should not be based on price or appearance alone. Evaluating a supplier’s production system, technical understanding, and consistency standards is far more important.

With the right manufacturing process, mindi wood furniture can perform reliably and protect your brand, rather than becoming a costly risk after delivery. When evaluated from a system and production standpoint, Mindi furniture can still make sense as a commercial investment for the right market segment.

Still Facing Issues with Mindi Wood Furniture?

Before committing to a bulk order, discuss your production requirements, material handling, and joinery standards with our team.

FAQ: Mindi Wood Furniture Defects

1. Why do defects in mindi wood furniture often appear after shipping, not during inspection?

Most defects appear late because Mindi wood reacts to moisture imbalance and climate change. Furniture can look stable at inspection while internal stress is still present, which only releases after shipping, storage, or adjustment to a new environment.

2. Are mindi wood furniture problems caused by the wood itself?

No. Most problems are not caused by the material, but by improper processing. When drying, joinery, and production standards are rushed or handled generically, defects become predictable outcomes.

3. What is the main manufacturing mistake that causes warping and cracking in mindi furniture?

The most common mistake is poor moisture control. Skipping gradual pre-drying and forcing the wood into kiln drying too quickly creates internal stress that later causes warping, twisting, or cracking.

4. What moisture content is safe for mindi wood furniture?

Mindi wood furniture should be produced with a moisture content below 12%, reached gradually through proper pre-drying and controlled kiln drying. Drying the wood too fast increases the risk of internal stress and delayed defects after delivery.

5. How can buyers reduce risk when sourcing mindi wood furniture from Indonesia?

Buyers should evaluate the supplier’s production system, not just samples or pricing. Asking about drying methods, joinery standards, and bulk consistency controls helps prevent defects after delivery.

Pictures Source:

- Tongue and Groove Picture: https://www.woodworkersjournal.com/cutting-tongue-groove-joints-table-saw/

- Tenon and Mortise Picture: https://www.wagnermeters.com/moisture-meters/wood-info/moisture/successful-wood-joints/

Hi, I’m Salman, founder of MPP Furniture, an Indonesian furniture manufacturer serving global retailers and project-based clients.

I began my career in my family’s export-oriented furniture company, gaining hands-on experience in production, construction, finishing, material performance, and product development. With a clear understanding of how international buyers evaluate furniture quality and reliability, I founded MPP Furniture to deliver export-ready products with consistent standards.

Here, I share insights from the perspective of a furniture manufacturer working directly with production teams on the factory floor, focusing on manufacturing and supplier evaluation.

Connect on LinkedIn

0 Comments