Rope furniture has become one of the most requested styles for outdoor and hospitality projects going into 2025 and 2026. Designers like it because it feels light and organic. Buyers like it because it looks modern but still warm. Yet behind the beauty, many importers and project buyers quietly ask the same question: Will this sag after a year of use?

This article answers that concern step by step. We start with the craft and history behind rope furniture, then move into the technical reasons sagging furniture happens, and finally explain how properly engineered rope furniture avoids this issue. If you source rope woven chair or outdoor rope furniture for commercial use, this guide is written for you.

Why Rope Furniture Exists and Why Buyers Love It

Rope furniture did not appear out of nowhere. Long before outdoor collections existed, woven seating was already part of furniture history.

Early versions used natural materials such as rattan peel, rush, and Danish paper cord. These were mainly for indoor use. They offered flexibility and comfort, but moisture and temperature changes limited their lifespan.

Modern rope furniture evolved when synthetic fibers entered the market. Today, most woven rope furniture uses polyolefin or olefin-based ropes. These materials were developed to handle outdoor conditions, including sun exposure and humidity.

Buyers choose rope furniture for three main reasons:

- Visual appeal: Rope adds texture and depth. It softens metal or wooden frames and works well in resorts, cafes, and poolside settings.

- Comfort: A rope-woven chair adapts to the body. It feels breathable compared to solid wood or plastic seating, especially in warm climates.

- Theoretical durability: Outdoor rope furniture is resistant to rot, dries quickly, and keeps its color better than many natural fibers.

In short, rope furniture promises both style and function. But a promise alone does not prevent sagging chair problems.

While rope is the gold standard for outdoors, we apply similar tension engineering to our indoor lines; discover 3 reasons why woven leather furniture is superior for climate-controlled spaces.

The Honest Problem: Sagging Is the Top Complaint

Sagging furniture is the most common complaint we hear about rope-woven bench and chair products. Many buyers experience this after six to eighteen months of use, especially in hospitality environments.

This is the moment where trust matters. Even retail guides now list sagging as a primary disadvantage of rope furniture when the weave is not tight enough. Rope furniture can be strong, but strength does not automatically stop sagging. Understanding why sagging happens helps buyers separate well-built products from decorative-only ones.

Sagging is just one variable; we recommend reading our outdoor weave material failure mitigation guide to understand the full scope of durability risks.

What Sagging Furniture Really Is

Sagging furniture happens when the seating surface stretches beyond its intended shape and does not return. Once this happens, comfort drops, appearance suffers, and replacement becomes likely.

There are three main technical reasons behind sagging chair issues:

1. Material creep under load

All flexible materials experience something called creep. This means the material slowly elongates when weight is applied over time. While polyolefin is durable and stain-resistant, it is a thermoplastic fiber that is flexible by nature. Even high-quality rope will stretch if it carries full body weight every day without support.

To better understand how flexible materials behave under stress, our guide to durable upholstery fabrics offers a helpful comparison of fiber resilience.

2. Heat and environmental exposure

Outdoor rope furniture lives under the sun. Heat softens synthetic fibers slightly. When combined with constant sitting pressure, the rope relaxes faster, especially in tropical or desert climates.

3. Lack of structural support

This is the most overlooked issue. Many rope-woven chairs rely on the rope alone to carry weight. In this design, the rope acts as both decoration and structure. Over time, this always leads to sagging furniture.

In practice, sagging is not caused by bad rope alone. It is caused by poor engineering choices.

Why “Strong Rope” Alone Is Not Enough

Suppliers often claim their rope is “high tensile” or “UV resistant.” These claims may be true, but they miss the point.

Rope is flexible by nature. Asking it to hold static weight without help is like using fabric as a beam. It may work at first, but physics always wins.

Commercial-grade outdoor rope furniture needs load-sharing. This means the weight must be distributed to something that does not stretch. This is where construction methods make the real difference.

How High-Quality Rope Furniture Is Engineered to Last

Well-made rope furniture does not depend on rope alone. It combines craftsmanship with hidden structural elements. Below is how durable rope-woven chair products are built in practice.

Frame preparation that locks the rope

Quality frames are prepared with grooves or channels, often called rabbet joints. These grooves prevent the rope from sliding under tension. When rope cannot move, it maintains its shape longer. This step also improves visual consistency because the weave stays aligned over time.

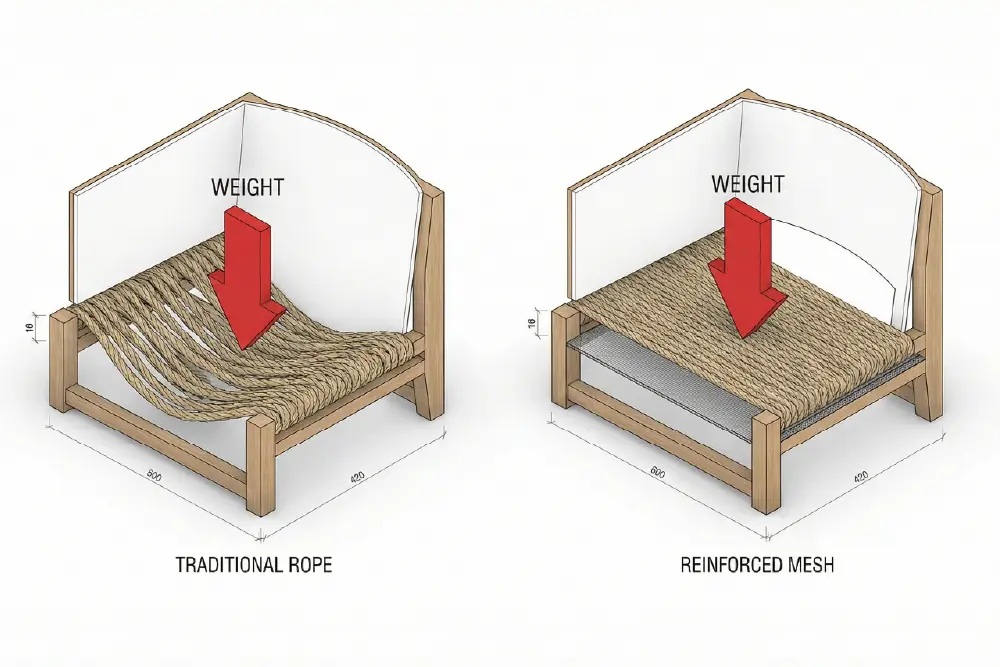

The nylon mesh underlayer

This is the most important difference between decorative rope furniture and commercial-grade products.

A nylon mesh or similar non-stretch support layer is installed beneath the rope weave. This layer carries the actual body weight. The rope above it provides comfort and design, not structure.

This principle is well-known in furniture restoration: without a proper foundation like webbing or springs, any seat will eventually sag regardless of the top material. Because nylon mesh has very low elongation, sagging furniture issues drop dramatically. The rope no longer needs to fight gravity alone.

Pre-tensioning during assembly

Pre-tensioning means tightening the rope beyond normal seating tension before final locking. This allows initial stretch to happen at the factory instead of at the customer site. After pre-tensioning, the rope is fixed permanently. This reduces early sagging chair complaints during the first year of use.

Quality control beyond appearance

Attention to detail matters. Proper inspection checks rope tension, mesh alignment, and frame stability before packing. This rigorous approach mirrors the durability standards found in lab testing, ensuring the furniture can handle repeated static loads. Skipping this step saves time, but leads to long-term problems for buyers.

Indonesian furniture suppliers treat rope furniture as an engineered product, not just a visual one.

How Buyers Can Spot Good Rope Furniture Quickly

You do not need lab equipment to judge rope furniture quality. Simple checks reveal a lot.

- Flip the chair over: This is the fastest test. If you see only rope underneath the seat, be cautious. If you see a support bar, sling, or mesh layer, the chair is designed to last longer.

- Do the press test: Press the seating surface firmly with your hand. Good rope-woven chair products will resist and bounce back. Excessive deflection usually means future sagging furniture problems.

- Ask direct construction questions: Ask the supplier if the rope is structural or decorative. Ask about under-seat support. Transparent suppliers will explain this clearly. Vague answers are a warning sign.

For retailers expanding their catalog, these quality checks apply across all woven categories, a standard we emphasize for Indonesian woven leather dining chair retailers as well.

Rope Furniture Can Last, If Built Right

Rope furniture deserves its popularity. It blends comfort, style, and outdoor performance in a way few materials can. Sagging is not an unavoidable fate, but it is unavoidable when design shortcuts are taken.

Durable rope furniture relies on:

- Proper frame preparation

- Non-stretch support layers, such as nylon mesh

- Controlled tension during production

- Consistent quality checks

For buyers, understanding these points changes how you source. You stop comparing only by price or appearance and start evaluating structure.

If you are sourcing rope furniture for commercial or long-term projects, work with Indonesian furniture manufacturers who are open about their construction methods and willing to explain the risks as well as the solutions.

In short, rope furniture is reliable when engineering supports the craft, not when beauty stands alone.

Your next best-seller might be here

Request a quotation and custom options tailored to your needs today via WhatsApp or email.

Frequently Asked Questions

Why does rope furniture sag over time?

Sagging furniture happens due to material creep, heat exposure, and lack of structural support under the rope weave.

Is sagging a defect or a design issue?

Most sagging chair problems come from design choices, not rope defects. Rope used as a structure will stretch over time.

Can outdoor rope furniture be used for hotels and restaurants?

Yes, if it uses proper support systems like nylon mesh and reinforced frames.

How long should quality rope-woven chairs last?

With correct engineering and normal commercial use, well-made rope furniture can last many years without visible sagging.

Is a thicker rope always better?

No. Thickness does not replace proper support. Structural design matters more than rope size.

I am a self-taught graphic designer with a deep passion for exploring the creative world through various tools and techniques. I have honed my skills in Adobe Illustrator, Photoshop, and Lightroom, while continuously expanding my knowledge by diving into After Effects and Premiere. Photography has become an integral part of my life, and I actively engage with it to capture moments and experiment with visual storytelling.

My fascination with color theory, histograms, and innovative design approaches drives my work, as I am always seeking new ways to push the boundaries of my creativity. From photography models and motion graphics to textures, collage, and surrealism, I am captivated by the endless possibilities in design and constantly strive to challenge myself with fresh and exciting ideas.

0 Comments