Many buyers source Indonesian furniture directly from manufacturers, expecting higher margins and better control. In practice, this approach often fails after the first shipment.

From our factory experience, most sourcing problems are not caused by design or price. They come from weak manufacturing control, poor material handling, and unclear responsibility during production. These issues rarely appear in samples; they surface months later in the market.

This guide explains what professional buyers should evaluate before choosing an Indonesian furniture manufacturer. It is written from a factory point of view, based on real production workflows rather than marketing claims.

Why Sourcing Indonesian Furniture Direct from Manufacturer Looks Profitable, But Often Fails

Sourcing Indonesian furniture directly from manufacturers often fails because buyers underestimate production control, not because of price or design issues.

Indonesia is one of the world’s strongest furniture sourcing countries because of material availability, skilled labor, and export experience.

Many Indonesian furniture manufacturers can produce custom designs at competitive costs. The problem is not the country. The problem lies in how buyers select their suppliers.

Most failures occur because buyers assume that every supplier calling itself a factory is a genuine manufacturer, that samples represent mass production, and that quality control occurs at the end rather than at the start.

Manufacturing Capability: How to Identify a Real Indonesian Furniture Factory

A real Indonesian furniture supplier controls production in-house, while risky suppliers depend on outsourced workshops with limited accountability.

1. What “In-House Manufacturing” Actually Means in Indonesia

In Indonesia, many suppliers operate as coordinators rather than true factories. They outsource production to multiple small workshops, which creates inconsistency and accountability issues.

A real Indonesian furniture manufacturer controls raw material preparation, component production, assembly, finishing, and packaging under one management system.

2. Why In-House Production Reduces Quality and Delivery Risk

When production is not owned by the factory, quality consistency and delivery responsibility become unclear.

Factories with in-house production can maintain consistent standards, manage realistic lead times, and take responsibility when problems arise. In practice, these differences separate real factories from risky suppliers.

Why Indoor and Outdoor Furniture Require Different Technical Standards

Many buyers assume that indoor and outdoor furniture require completely different production flows. In reality, the main workflow can look similar. Not every factory manages these details correctly.

The real difference lies in the technical details. Problems happen when factories treat those details as interchangeable. The risk is not using one system; the risk is ignoring where the system must change.

For buyers sourcing Indonesian furniture, understanding these differences helps prevent failures that usually appear after shipment, not during sampling.

1. Wood Treatment: Moisture Content Is Non-Negotiable

For export-grade Indonesian furniture, wood moisture content must be consistently below twelve percent before production begins.

For both indoor and outdoor furniture, wood must be properly dried. For outdoor products, the tolerance is much lower. Moisture content should be consistently below twelve percent before production starts.

When moisture content is not controlled at this level, wood movement becomes inevitable. Cracking, warping, and joint stress usually appear months later, when products are already in use.

2. Construction Details Must Allow Natural Wood Movement

Furniture construction must allow wood to move naturally, especially for outdoor products exposed to climate changes.

Outdoor construction cannot copy indoor logic. Table designs often require slat construction to allow natural wood movement. Using solid panels in outdoor conditions increases the risk of cracking and deformation.

For woven seating, materials must be outdoor-grade. This includes the weaving material and the cushion system. Using indoor-grade materials outdoors may look acceptable in samples, but it fails quickly in real use.

3. Finishing Systems Must Match Product Usage

Most furniture failures after shipment originate from finishing systems that are not designed for the product’s end environment.

Outdoor furniture requires outdoor-grade finishing systems. Visual similarity to indoor finishes does not mean functional suitability. Outdoor finishes are designed to handle exposure, humidity changes, and temperature variation.

Applying indoor finishing systems to outdoor furniture is one of the most common technical mistakes in Indonesian furniture sourcing.

Material Selection and Control: Where Most Quality Problems Begin

1. Why Wood Problems Usually Start Before Production Begins

Most buyers focus on the final inspection. In reality, quality problems often start with material selection and drying. Once unstable material enters production, finishing cannot fully correct it.

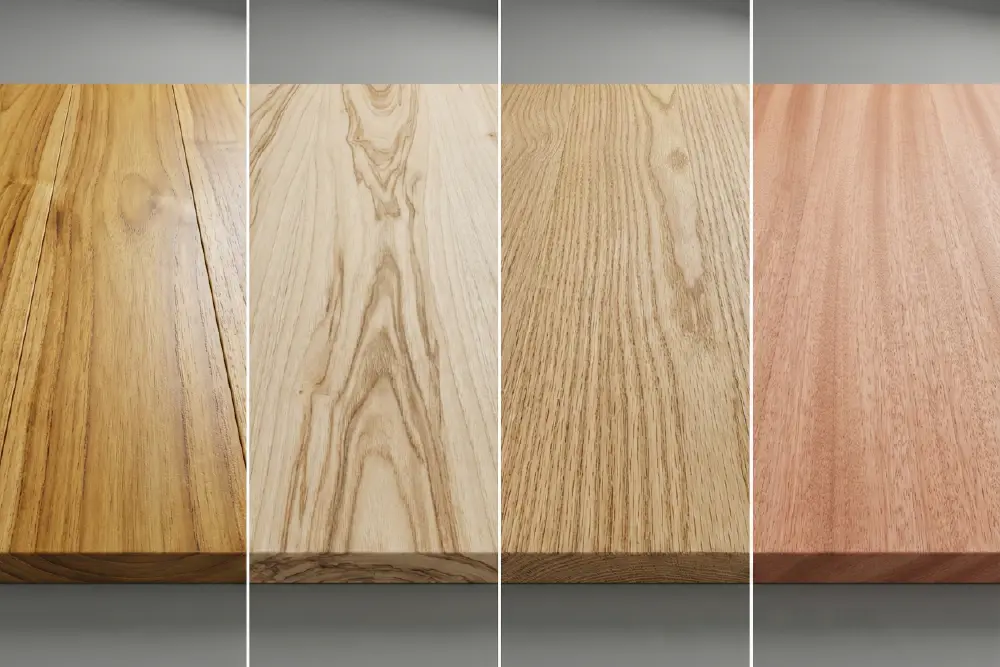

2. How Material Mixing and Poor Drying Create Long-Term Risk in Indonesian Teak, Sungkai Wood, and Mindi Wood

Different woods behave differently. Indonesian teak contains natural oil that requires controlled drying and sealing.

Sungkai wood is lighter and fast-growing, making it sensitive to moisture imbalance. Mindi wood offers good aesthetics but needs careful control in humid environments.

When materials are mixed without aligned drying standards, long-term instability often appears after six to twelve months rather than during sampling.

Construction Quality: What Determines Durability After 6–12 Months

Construction problems usually appear after products reach end customers, not while they are still inside the factory. From production experience, the most common failures are cracked joints and broken wood around connection points.

These issues are rarely visible in samples. Problems start when joinery looks correct visually but is wrong structurally. Mortise and tenon joints that are too loose lack strength. Joints that are too tight leave no space for glue to spread evenly. Both conditions create stress that leads to cracking and joint failure months later.

This is why construction quality cannot rely on appearance alone. Proper tolerance, joint balance, and consistency across mass production determine whether furniture survives real use.

Why Improper Finishing Causes Furniture Failure After Shipment

Finishing failures are one of the most common sources of complaints after furniture reaches the market. The issues buyers report most often are peeling and fading, especially on outdoor products.

Finishing should be treated as a protective system, not a visual layer. Outdoor furniture requires outdoor-grade finishing that can handle exposure, humidity changes, and temperature shifts. Using indoor finishing systems outdoors may look acceptable during sampling, but fails quickly in real conditions.

At MPP, finishing systems are not chosen based on appearance alone. For every new sample, the finishing specification is discussed directly with Propan to ensure the coating matches product usage and market conditions.

How MOQ and Quality Control Reflect Factory Readiness

MOQ and quality control only work when the factory controls the production flow from start to finish.

MOQ is often misunderstood as a pricing issue. In practice, it is a production control issue. While MPP offers flexible MOQ starting from small quantities, complexity increases as the number of SKUs inside one container grows.

When too many variations are forced into one container, production planning becomes fragmented. This increases the risk of inconsistency, missed checks, and delayed correction.

Samples must follow the same SOP as mass production. If samples are treated as one-off pieces, they cease to accurately represent real production results.

Quality control is most effective when applied throughout production, not just at the final inspection. This approach allows problems to be corrected before they turn into costly claims.

Why Experienced Buyers Choose MPP as Their Long-Term Manufacturing Partner

Expertly Handcrafted with Controlled Production Standards

Every product is handcrafted by skilled teams supported by calibrated machinery. Production is managed in-house to maintain consistency from sample to shipment.

Attention to Detail That Protects Buyers from Hidden Quality Issues

Material control, construction checks, and finishing workflows are handled with precision. Quality control is applied throughout production, not only at the end.

A Reliable Manufacturer Built for Long-Term B2B Partnerships

MPP works as a long-term manufacturing partner by offering free consultation, free product development, and a clear process from design to export.

Two decades of manufacturing expertise in wood and natural materials for global B2B projects.

Long-term relationships with retailers and importers who rely on consistent quality and service.

Extremely low complaint and defect rate, supported by strict in-house quality control at every stage.

Predictable lead times, stable production, and consistent specifications across repeat orders.

Final Checklist Before You Choose an Indonesian Furniture Manufacturer

Choosing the right Indonesian furniture manufacturers is not about finding the cheapest offer. It is about reducing risk while building a stable supply chain.

A safer decision comes from checking real manufacturing discipline. Look at in-house production, material moisture control, construction standards, finishing suitability, and how clearly the factory communicates during production.

This is how buyers protect their brand and avoid problems that only appear after the furniture reaches the market.

If you are planning to source Indonesian furniture, start by verifying how the factory produces, not just what it promises.

Planning your next best-selling collection?

Request catalog, pricing info, MOQ, and custom options today — we’ll respond quickly.

Frequently Asked Questions

1. Is it safe to source Indonesian furniture directly from manufacturers?

Yes, it is safe when the factory controls production in-house. Problems usually occur when suppliers rely on outsourced workshops and cannot take full responsibility for quality and delivery.

2. What is the main risk when sourcing Indonesian furniture?

The main risk is weak manufacturing control, not pricing. Issues like poor wood drying, inconsistent construction, and rushed finishing often appear after shipment, not during sampling.

3. What moisture content is acceptable for export-quality wooden furniture?

Export-quality Indonesian furniture should use wood with a moisture content below 12% before production. Higher levels increase the chance of cracking, warping, and joint stress after delivery.

4. How can buyers identify a real Indonesian furniture manufacturer?

A real manufacturer manages material preparation, production, finishing, and packaging under one system. Suppliers who act mainly as coordinators usually cannot guarantee consistency at scale.

5. Why do furniture samples look good but fail in bulk production?

Samples are often made with extra time and attention. Failures happen when factories lack standardized processes and quality checkpoints during mass production.

Hi, I’m Salman, founder of MPP Furniture, an Indonesian furniture manufacturer serving global retailers and project-based clients.

I began my career in my family’s export-oriented furniture company, gaining hands-on experience in production, construction, finishing, material performance, and product development. With a clear understanding of how international buyers evaluate furniture quality and reliability, I founded MPP Furniture to deliver export-ready products with consistent standards.

Here, I share insights from the perspective of a furniture manufacturer working directly with production teams on the factory floor, focusing on manufacturing and supplier evaluation.

Connect on LinkedIn

0 Comments