For more than three centuries, mahogany furniture defined what "fine furniture" meant. It was the wood behind heirloom cabinets, stately dining tables, and architectural interiors that survived generations without losing its form or relevance.

Over the last decade, however, mahogany receded from mainstream collections. Lighter woods, pale finishes, and minimalist interiors dominated global demand. Retailers favored faster-growing alternatives, and designers leaned toward woods that visually disappeared rather than asserted themselves.

That cycle is now ending.

In 2025, the furniture market is undergoing a clear shift. Designers are moving away from sterile minimalism toward warm maximalism, layered interiors, and materials that add visual weight and emotional depth. Simultaneously, professional buyers are becoming more cautious about material performance, compliance risk, and long-term value.

Mahogany sits precisely at the intersection of these changes. Rather than being driven by nostalgia, this return relies on engineering logic, material science, and market reality.

Defining True Mahogany vs. Substitutes

The term "mahogany" is widely used, but rarely understood. For professional buyers, this misunderstanding creates both performance risk and regulatory exposure.

True mahogany belongs to the Swietenia genus, native to the Neotropics. Among its species, Swietenia macrophylla has historically been the most valued for furniture and cabinetry due to its stability and workability.

As natural forests were depleted in the past, mahogany cultivation shifted toward managed plantations. Today, export-grade genuine mahogany is primarily sourced from regulated plantations in regions such as Fiji and Indonesia, where growth cycles, harvesting, and documentation are tightly controlled.

Concurrently, the global market introduced other woods under the mahogany label. African mahogany (Khaya spp.) became a widely used successor, while unrelated species such as Shorea were marketed as "Philippine mahogany."

From a commercial standpoint, these distinctions are not academic. They determine the wood's behavior after machining, its response to humidity, and its legal status in certain markets.

Structural Stability and Technical Properties

Mahogany's reputation is rooted in its internal structure rather than its appearance.

At the microscopic level, mahogany contains marginal parenchyma bands, which regulate moisture exchange within the wood. This anatomical feature slows and evens out dimensional movement when environmental humidity changes.

This directly affects furniture performance. Wood that absorbs and releases moisture unevenly tends to cup, twist, or split. Mahogany resists these movements better than most commonly used hardwoods.

Its density sits in a balanced range, with a specific gravity typically between 0.52 and 0.59. This places it squarely between lightweight tropical species and dense temperate hardwoods. The result is a material that feels substantial without creating internal stress.

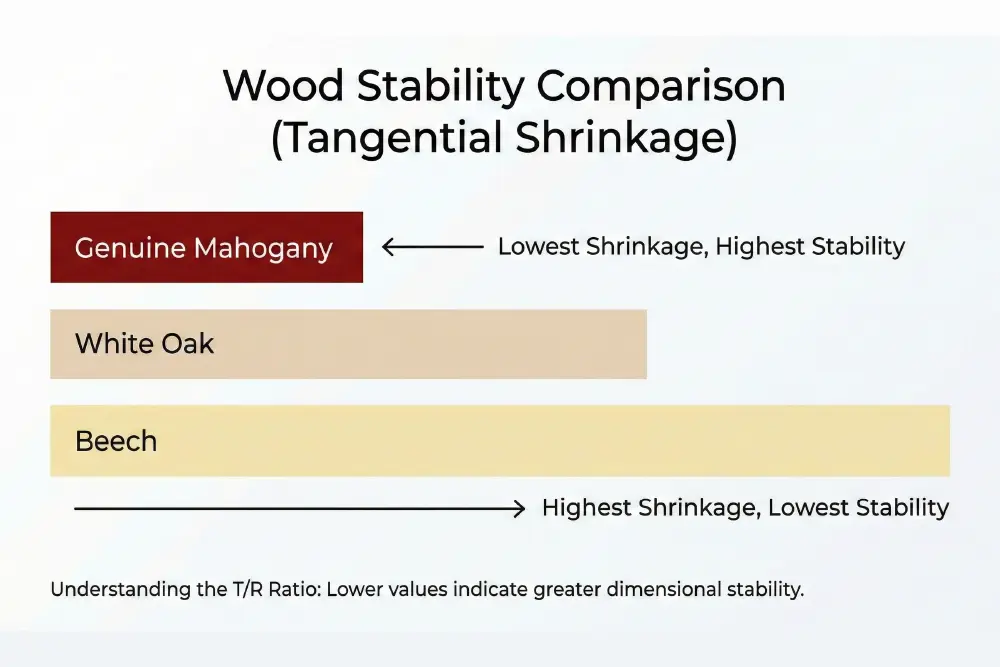

Most critically, mahogany has a low tangential-to-radial shrinkage ratio, typically around 1.4. This ratio explains why wide mahogany panels remain flat and why joints stay tight over decades. By comparison, many domestic hardwoods exhibit higher ratios, leading to visible seasonal movement.

For furniture manufacturers and buyers, this stability translates directly into fewer claims, longer product life, and higher customer satisfaction.

To see how we apply these principles in production, review our technical guide on mitigating wood movement risk.

Shipping Stability: Preventing Transit Damage

The most dangerous phase for furniture is often the journey from the factory to the showroom. Shipping from a tropical manufacturing hub to a temperate retail environment exposes wood to "climate shock"—rapid humidity drops that fracture less stable species. Mahogany’s low shrinkage ratio acts as an insurance policy during this transition. Its internal structure releases moisture gradually rather than abruptly, ensuring that containers arrive with inventory intact and ready for sale, protecting importers from the costly repairs and write-offs common with more volatile hardwoods.

Hardness, Workability, and Carving Precision

With a Janka hardness of approximately 900 lbf, mahogany occupies a functional sweet spot between dense temperate hardwoods and lightweight tropical species. Significantly harder than Sungkai, it maintains crisp edges and resists abrasion, yet it avoids the excessive hardness of Oak, which often makes detailed shaping labor-intensive.

This balance is evident in direct comparison. Sungkai is prone to surface compression, causing fine carved details to lose definition in high-touch areas. Conversely, while Teak is the standard for an outdoor furniture manufacturer, its silica and oil content increase cutting resistance, accelerating tool wear, and risking fiber tearing during intricate work.

Mahogany resolves this compromise, offering enough density to lock details in place while remaining cooperative under the chisel.

Structurally, the wood allows for clean fiber severance, where tools shear smoothly rather than crushing the grain. This enables controlled curves and sharp transitions that softer woods cannot sustain, without the brittleness or resistance common in harder species.

This logic explains mahogany’s historical dominance in heirloom furniture. Craftsmen favored it because it permitted deep, complex motifs that retained their form for decades. Today, that same combination of workability and shape retention makes it the preferred choice for high-end interiors demanding precision and visual authority.

If your project requires a lighter palette or a different density profile, explore the technical specifications of Sungkai wood furniture as an alternative.

The Three Market Grades: Genuine, African, and Substitutes

Genuine Mahogany: The Benchmark for Stability and Legacy Value

Genuine mahogany (Swietenia macrophylla) defines the investment-grade benchmark, primarily due to its exceptional dimensional stability. With a balanced density and low tangential-to-radial shrinkage ratio, it remains predictable in wide panels and complex joinery, cementing its status as the material of choice for heirloom cabinetry and architectural work.

Its secondary advantage is superior workability. The wood machines cleanly and accepts finishes evenly, allowing for refined designs with minimal correction. Commercially, this translates to strong resale value, as buyers recognize the genus as a premium asset.

Constraints lie in availability and regulation. Long growth cycles and CITES Appendix II listing drive up costs and demand strict traceability. For buyers, this necessitates rigorous sourcing but ensures a product with verifiable legacy value.

African Mahogany: Visual Impact With Greater Technical Demands

African mahogany (Khaya spp.) serves as a visual successor, favored for its dramatic ribbon-stripe or interlocked grain. This figure offers a bold, expressive aesthetic that appeals to markets prioritizing visual impact over uniformity.

Technically, it presents greater variation than its Neotropical counterpart. Density fluctuates between boards, and the characteristic interlocked grain introduces machining risks like tear-out. Achieving a clean surface requires patience and specific tooling that genuine mahogany does not demand.

The trade-off is manufacturing sensitivity versus cost. While accessible, it demands expert drying and finishing to prevent defects. With recent regulatory tightening on specific Khaya populations, sourcing now requires similar diligence to Swietenia.

Mahogany Substitutes: Cost Efficiency With Clear Limitations

The third tier comprises botanically unrelated substitutes, most notably Shorea species marketed as "Philippine mahogany." These are defined by nomenclature rather than biological properties.

Their primary asset is volume. Fast-growing and inexpensive, they suit budget-driven applications where availability outweighs technical precision.

Performance limitations are significant. Lacking the stability and carving retention of true mahogany, these woods pose a reputational risk when positioned as luxury materials, as they are prone to seasonal movement and degradation.

Summary: Quick Comparison of Mahogany Types

| Feature | Genuine Mahogany (Swietenia) | African Mahogany (Khaya) | Substitutes (Shorea/Other) |

| Stability (T/R Ratio) | Excellent (Balanced & Predictable) | Moderate (Variable) | Low (Prone to movement) |

| Workability | Superior (Crisp details, clean cuts) | Challenging (Interlocked grain) | Fair (Softer, less precise) |

| Market Value | Investment Grade | Mid-Range | Entry-Level / Budget |

| Primary Risk | Cost & Availability | Machining Tear-out | Durability & Branding |

Design Trends: Mahogany in 2025 Interiors

The 2025 design landscape marks a decisive departure from sterile minimalism, embracing Warm Maximalism and Organic Modern aesthetics. These interiors require furniture that anchors layered, grounded spaces with emotional depth, rather than pieces that recede into anonymity.

This shift imposes strict material prerequisites: visually, woods must offer rich grain complexity to avoid flatness; structurally, the emphasis on expansive statement pieces—such as architectural sideboards and large dining tables—demands raw materials capable of maintaining dimensional stability across wide spans.

Mahogany answers these needs through its inherent physical properties. Its deep, reddish-brown tone and chatoyant grain deliver immediate warmth, while its low shrinkage ratio allows designers to specify the substantial, seamless panels these expressive forms require without risking long-term movement.

In this context, mahogany succeeds where lighter woods fail. While pale species can appear insubstantial or washed out against rich textures, mahogany provides visual weight, ensuring that the ambition of the design is matched by the reliability of the structure.

Consequently, mahogany’s resurgence represents a functional alignment rather than a fleeting trend. The current market treats presence and longevity as expectations, and mahogany fulfills them through material reality rather than styling, making it the definitive wood for the 2025 interior.

Comparison: Mahogany vs. Walnut, Oak, and Teak

In Warm Maximalism and Organic Modern interiors, material selection is no longer a popularity contest; it is about choosing wood that balances visual presence with structural confidence. While Walnut, White Oak, and Teak contend for this space, mahogany consistently proves the most versatile engineering choice when evaluated against the demands of modern interiors.

Walnut: High Warmth, Higher Volatility

Walnut is often used in warm, expressive interiors because of its naturally dark tone. Visually, it aligns well with layered spaces and sophisticated palettes. The limitation appears in scale and consistency. Walnut is denser and more brittle than mahogany, making it less forgiving in wide panels and intricate joinery.

In large case goods or architectural cabinetry, walnut requires stricter environmental control to prevent cracking or joint stress. Mahogany, by contrast, offers similar visual richness while remaining more dimensionally predictable, allowing designers to specify larger surfaces and tighter tolerances without increasing long-term risk.

White Oak: Strength Without Stability in Form

White Oak, especially in darker stains, also appears in Organic Modern and Classic-Modern interiors. Oak provides strength and familiarity, but its higher tangential movement introduces challenges when designs move beyond simple, rectilinear forms.

In interiors that favor layered detailing, curved components, or mixed materials, oak's seasonal movement becomes more visible over time. Mahogany outperforms oak in these contexts because its lower movement allows complex designs to remain visually composed, even as humidity changes. This makes mahogany a safer choice for furniture that is meant to look intentional rather than purely functional.

Teak: The Outdoor King Struggling Indoors

Teak enters these styles primarily through its association with luxury and longevity. While teak performs exceptionally well outdoors, its properties are less aligned with the demands of refined interior furniture. Its high oil content complicates finishing, especially in darker or more nuanced tones, and its hardness resists fine detailing.

In Warm Maximalist and Classic-Modern interiors, where intricate profiles, smooth transitions, and controlled surfaces matter, teak often feels visually heavy and technically restrictive. Mahogany, on the other hand, accepts finishes evenly, supports delicate detailing, and delivers warmth without overpowering the surrounding space.

Mahogany outperforms these woods not by excelling at one extreme, but by avoiding their weaknesses. It balances depth without brittleness, strength without excessive movement, and richness without visual heaviness. In interiors that demand furniture to function as both structure and statement, this balance becomes decisive. Mahogany allows designers and buyers to pursue expressive forms, darker palettes, and layered compositions without sacrificing stability or long-term performance.

Strengths and Limitations

Mahogany’s enduring relevance stems from its ability to unify dimensional stability, balanced hardness, and workability into a single material profile. Unlike species that force a choice between durability and detail, it supports refined joinery and intricate carving while developing a richer patina over time, positioning it as the logical foundation for investment-grade furniture.

This balance, however, implies specific physical boundaries. Being moderately hard rather than stone-like, mahogany is more susceptible to surface indentation than Oak or Teak. This is not a structural flaw but a characteristic that demands intelligent finishing and placement to mitigate impact risks in high-traffic environments.

Commercially, the primary constraint is sourcing complexity. Genuine mahogany involves higher costs driven by CITES regulation, while African mahogany presents manufacturing hurdles due to interlocked grain. Consequently, the material demands a disciplined supply chain; without transparent sourcing and expert handling, these trade-offs can escalate from manageable costs to points of failure.

Recommended Furniture Applications

Material selection for mahogany is rarely random; it follows a strict functional logic connecting dimensional stability to specific furniture typologies. Understanding its best application means examining how the wood behaves once shaped, joined, and subjected to environmental stress.

In case goods—sideboards, cabinets, and storage units—mahogany’s low movement profile is the primary asset. It ensures wide panels remain flat and joinery stays tight despite humidity fluctuations, while its cooperative grain allows for the tight tolerances and smooth drawer action that define high-quality cabinetry.

For chairs and architectural components, the material's ability to hold detail without brittleness is decisive. Unlike softer woods that lose definition or harder species that resist the chisel, mahogany allows for clean, stress-free cutting, enabling complex curves and moldings to retain their structural clarity over decades.

For an experienced Indonesian furniture manufacturer, these characteristics dictate handling across styles. Whether deployed for the intricate carving of antique reproductions or used as a stable structural core for contemporary mixed-material designs (pairing with rattan or upholstery), mahogany is chosen to guarantee precision where other materials might falter.

Suitability for Hand-Carving

For Indonesian artisans, mahogany acts as a medium for heritage capability rather than a simple raw material, unlike automated CNC milling, which is limited to vertical axes. Traditional hand-carving exploits mahogany’s tight grain to execute deep undercuts and complex organic curves without chipping. This material cooperation allows for a level of three-dimensional detail and negative space that mass-production methods cannot replicate, transforming furniture from a manufactured product into a sculpted asset.

For a deeper look at the production logic behind organic shapes, read our article on the process behind curved furniture manufacturing.

Finishing Properties and Chemical Compatibility

Beyond structural stability, mahogany offers distinct chemical advantages in the finishing room. Unlike Oak, which contains high levels of tannins that can react with water-based coatings or bleed through light stains, mahogany is chemically neutral. Its semi-open pore structure provides further versatility: it readily accepts grain fillers for high-gloss traditional aesthetics, yet remains equally effective with open-pore, matte finishes preferred in Organic Modern designs. This flexibility allows retailers to adapt a single material across diverse style collections without risking chemical incompatibility.

Commercial Durability: Solid Wood vs. Veneer

In high-traffic hospitality or retail environments, the choice between solid mahogany and veneer is a calculation of lifecycle cost. While veneer offers lower upfront pricing, it remains vulnerable to delamination and edge-chipping that cannot be repaired without replacement. Solid mahogany, conversely, withstands impact; dents can be steamed out, and scratches sanded down, extending the asset's usable life. For commercial projects, this repairability delivers a superior return on investment, ensuring the furniture maintains its aesthetic value long after veneer alternatives would require disposal.

Discover why these durability factors make solid wood the preferred standard in our analysis of mahogany as a choice for luxury resort furniture.

Sustainability, Regulations, and Compliance

Sustainability and regulation now function as primary market forces rather than background concerns. Mahogany’s history of overharvesting necessitated a global regulatory framework that has fundamentally reshaped how professional buyers manage sourcing, specification, and long-term planning.

CITES Appendix II governs the trade of all Swietenia species and, since 2023, significant Khaya populations. These conditions require every shipment to carry a Non-Detriment Finding and verified export permits, a process that systematically eliminates informal supply chains and rewards compliant, transparent producers.

This regulatory pressure impacts every buyer segment. Retailers increasingly scrutinize product claims to avoid the legal and reputational risks of mislabeling, while designers specify certified mahogany to meet rising client expectations for responsible, ethical sourcing.

Importers face the most direct risk, as non-compliant shipments invite port seizures and severe financial losses. Compliance now functions as a powerful demand driver. Buyers increasingly prioritize operational assurance and reliability alongside the wood's inherent technical properties.

Beyond CITES, the industry is adjusting to FSC certification as a baseline and the upcoming European Union Deforestation Regulation (EUDR). These standards favor manufacturers capable of providing precise geolocation data and digital traceability, prioritizing vertically integrated operations over fragmented supply models.

Indonesia anchors this regulated landscape, providing approximately 18% of the global supply through a mature, plantation-based ecosystem. Leading Indonesian furniture manufacturers utilize established infrastructure and kiln-drying expertise to meet these stringent documentation needs, positioning Indonesian furniture suppliers as the most stable partners for buyers navigating a resource-constrained global market.

Navigate these complex requirements confidently with our step-by-step EUDR and SVLK guide to sourcing compliant mahogany.

Value for Retailers, Designers, and Buyers

Mahogany’s commercial value varies by stakeholder, presenting distinct benefits and constraints for retailers, designers, and end users. Understanding these distinctions is critical for ensuring that material expectations align with the final product's positioning and performance.

For Retailers: Premium Positioning With Higher Responsibility

For retailers, mahogany provides a significant branding lever, anchoring collections in the premium segment through its historical prestige and visible quality. Its association with investment value justifies higher price points, while its visual depth ensures pieces stand out in high-end showrooms and digital galleries.

Retailers must manage inventory risks through precise species labeling and customer education. Given the longer sales cycles typical of investment-grade furniture, success depends on moving away from commodity-driven volume toward a strategy that rewards deep material knowledge and regulatory transparency.

For Designers and Architects: Creative Freedom With Technical Boundaries

Designers utilize mahogany as a versatile engineering tool, relying on its stability to execute bespoke, built-in applications and large-scale architectural joinery. It provides the material authority needed to anchor complex, layered interiors while integrating seamlessly with diverse textures like stone, metal, and upholstery.

Creative use requires technical discipline; designers must account for mahogany's moderate hardness in high-impact zones and manage its deep tones to avoid overwhelming smaller spaces. Selective, intentional application prevents the visual heaviness that can result from undisciplined usage.

For End Buyers: Long-Term Value With Care Expectations

For end users, mahogany represents a shift from disposable consumption to heirloom investment. Its ability to age gracefully and remain structurally sound over decades reinforces the perception of value, rewarding buyers with furniture that improves in character and patina as it matures.

This longevity requires a baseline of care; buyers must prioritize appropriate placement to avoid UV-induced fading and surface impact. While the upfront cost is higher, the return is a durable, repairable asset that outperforms synthetic or lower-grade timber alternatives.

Conclusion: The Next Step for Professional Buyers

Beyond its historical prestige, mahogany’s status as the 'king of hardwoods' is now secured by verifiable material science and proven market resilience. As demand shifts toward Warm Maximalism and investment-grade interiors, the opportunity for retailers and designers is significant.

Capturing this value requires more than selecting a wood species. It demands a rigorous approach to sourcing. Professional buyers must prioritize suppliers who can demonstrate full regulatory compliance—specifically CITES and EUDR documentation—while providing transparent technical data on moisture content and provenance. By partnering with a capable Indonesian furniture manufacturer or verified supplier, buyers secure not just a raw material but a guarantee of longevity and performance.

For those ready to integrate mahogany into upcoming collections, the path forward begins with requesting detailed material specifications and verifying supply chain transparency. In a market defined by scrutiny and high expectations, this diligence turns a classic material into a modern competitive advantage.

Your next best-seller might be here

Request a quotation and custom options tailored to your needs today via WhatsApp or email.

Frequently Asked Questions

Is mahogany a hardwood?

Yes, mahogany is a tropical hardwood (Swietenia) valued for its balanced density. With a Janka hardness of ~900 lbf, it occupies a functional 'sweet spot' that remains significantly harder than softwoods like Sungkai for durability, yet less abrasive than Oak or Teak. This allows for superior carving and machining precision without causing excessive tool wear.

Is mahogany wood expensive?

Yes, mahogany commands an investment-grade premium driven by 20+ year plantation growth cycles, strict CITES compliance costs, and superior dimensional stability. While upfront pricing exceeds commodity woods, the material's longevity and established resale value in the high-end market often offset the initial cost.

Is mahogany furniture sustainable?

Sustainability depends on supply chain transparency. Modern mahogany from regulated plantations in Indonesia and Fiji operates under CITES Appendix II guidelines to prevent overharvesting. Verification requires a Non-Detriment Finding (NDF) and EUDR compliance documentation to confirm legal and ethical provenance.

What is the difference between Genuine and African Mahogany?

Performance and botany define the difference. Genuine Mahogany (Swietenia macrophylla) represents the investment standard and provides the superior dimensional stability required for wide panels. African Mahogany (Khaya spp.) offers a similar aesthetic with dramatic ribbon-stripe grain but presents greater manufacturing challenges, specifically interlocked grain that creates tear-out risk.

Can mahogany be used outdoors?

Mahogany possesses natural durability and rot resistance but lacks the high natural oil content of Teak (Tectona grandis). Use in outdoor settings requires marine-grade sealing to prevent UV degradation and surface checking. While mahogany excels in protected architectural or semi-outdoor applications, Teak remains the superior choice for maintenance-free exposure.

I am a self-taught graphic designer with a deep passion for exploring the creative world through various tools and techniques. I have honed my skills in Adobe Illustrator, Photoshop, and Lightroom, while continuously expanding my knowledge by diving into After Effects and Premiere. Photography has become an integral part of my life, and I actively engage with it to capture moments and experiment with visual storytelling.

My fascination with color theory, histograms, and innovative design approaches drives my work, as I am always seeking new ways to push the boundaries of my creativity. From photography models and motion graphics to textures, collage, and surrealism, I am captivated by the endless possibilities in design and constantly strive to challenge myself with fresh and exciting ideas.

0 Comments