Buying Indonesian tables is one of the highest-risk decisions in furniture sourcing. From real export production experience, many tables look perfect at inspection but fail months after shipment.

Cracks, warping, wobbles, and finishing failure are rarely caused by bad wood. As an Indonesian furniture manufacturer, we see these defects come from poor engineering decisions: moisture content that is still too high, table construction that locks wood movement, and finishing chosen for appearance instead of wood performance.

This article is written from a real manufacturer’s perspective to explain why table defects often appear after shipment, what technical factors buyers must understand before ordering from Indonesian furniture suppliers, and how to evaluate table construction beyond samples to reduce post-shipment risk.

Why Tables Are One of the Highest-Risk Furniture Categories

Tables look simple, but structurally, they are unforgiving. Unlike chairs, a table carries a continuous static load every day. The tabletop must remain flat, stable, and visually acceptable at all times, not just new.

The risk increases because tables rely on wide, flat surfaces. Wide panels amplify wood movement caused by changes in humidity. Even small mistakes in moisture content, panel construction, or allowance for movement can lead to cracking, cupping, or uneven surfaces that customers immediately notice.

From a business perspective, table defects are also harder to manage. A cracked or warped tabletop usually cannot be repaired without replacing the entire piece. For retailers, one failed table leads to returns, refunds, and negative reviews that not only affect a single SKU but also your brand reputation.

Why Indonesian Table Defects Appear After Shipment, Not During Factory Inspection

Most table defects do not appear during factory inspection because the failure mechanism is time-based. At the factory stage, the table has not yet experienced climate change, prolonged load, or repeated daily use.

After shipment, the tables move from Indonesia’s humid environment into a different climate. As moisture levels equalize, internal stress that was locked inside the wood begins to release. This process happens gradually, which is why cracks, warping, and joint movement often appear months later, not at loading.

Quality control checks surface appearance and basic stability, but it cannot simulate long-term humidity cycles or real customer usage. Inspection also cannot fully reveal what happens inside the table structure, including whether internal construction and joinery are engineered correctly to handle long-term load and wood movement.

This is why buyers often feel confident at inspection, yet still face defects later in the market. The issue is not missed inspection; it is that the risk was already built into the product during early production decisions.

The Most Common Table Defects and the Business Risk Behind Them

When Indonesian table defects occur, they rarely stay limited to technical complaints. Table failures quickly turn into commercial problems because tables are large, visible, and difficult to justify once customers experience issues.

Unlike minor defects that can be overlooked, Indonesian table problems are exposed the moment the product is used. Tables are touched, leaned on, and relied on every day. Customers immediately feel instability when a table wobbles, see cracks forming across the tabletop, or notice finishing degrading unevenly.

Because tables are functional centerpieces, these defects are hard to explain away. They directly damage customer trust and store credibility, which is why table-related complaints escalate faster than issues in most other furniture categories.

Cracking on Tabletops and Structural Panels

Cracking is the most expensive table defect because it often affects the tabletop itself. Once a tabletop cracks, repair is rarely acceptable in retail markets. Most cases end with full replacement, additional logistics costs, and dissatisfied customers.

Cracks usually signal deeper problems related to moisture imbalance or construction that restricts natural wood movement, as commonly found in common wood defects in Indonesian furniture. When this happens after shipment, the buyer absorbs the cost, not the factory.

Warping and Cupping on Wide Table Surfaces

Warping and cupping create uneven surfaces that make tables uncomfortable and visually unacceptable. Even small deviations are easy for customers to notice, especially in dining or working environments where flatness is expected.

Because tables rely on wide, flat panels, this type of defect directly affects usability. Customers rarely tolerate explanations about wood behavior when the table surface no longer feels level.

Wobble and Joint Movement Over Time

Wobble usually develops gradually as joints loosen under continuous static load. A table that feels unstable, even slightly, is often perceived as poor quality regardless of wood species or price point.

This defect often points to internal construction issues, such as improper joinery or tolerances that were not designed for long-term load and movement.

Why Indonesian Tables Crack, Warp, or Become Unstable Over Time

From our experience as an Indonesian furniture manufacturer, table defects start with how early production decisions are made, not with what happens after shipment. Wood often enters production before moisture content is truly stable, and table construction is sometimes designed for speed or appearance instead of how the table will behave under constant load.

What buyers experience later is the outcome of those decisions: cracking on tabletops, warping on wide surfaces, and joint movement that causes wobble.

These problems come from unstable moisture content, incorrect top-table joinery, weak support construction under the tabletop, and poor leg-to-top connections, all of which relate to how wood movement is managed in table construction, particularly in wide, load-bearing surfaces.

Together, they lock stress into the structure, which is released only after shipment through daily use and climate change.

Moisture Content Control

From our experience, in table production, the tabletop moisture content must be below 12% before production begins, which aligns with why moisture content below 12% is critical to preventing cracks after shipment, especially in wide tabletops.

Wood is a living material that continuously absorbs and releases humidity. If moisture is still too high, movement is unavoidable once the table enters a new climate.

Moisture content between components does not need to be identical, but it must be uniform and controlled. When boards joined into a tabletop have significantly different moisture levels, they will move at different speeds. This imbalance increases the probability of cracking because stress concentrates along glue lines and joints.

A critical warning sign appears when a tabletop already shows bending or curvature on the production floor. From experience, once a tabletop starts moving before shipment, the risk of cracking after export rises sharply. At that point, the problem is no longer cosmetic; it is structural and will likely surface in the market.

Top-Table Joinery: Why We Use Tongue and Groove

We use tongue and groove joinery for tabletops because it is simple, strong, and proven over many years of table production. More importantly, it is a joinery system we can execute consistently and accurately with our current machinery, which is critical for export tables that must perform after shipment.

Finger joint construction requires specialized machines and extremely high precision. If finger joints are not cut and pressed with exact tolerances, boards may not seat correctly and can introduce internal stress. Because we do not yet operate dedicated finger‑joint machinery for wide tabletops, we choose not to force this method.

Instead, tongue and groove provides reliable alignment, sufficient glue surface, and controlled movement across wide panels. For us, the safest joinery is not the most complex one, but the one that can be produced repeatedly with predictable performance in real export conditions.

Support Construction Under the Tabletop

As a furniture manufacturer, in reality, supporting construction under the tabletop is as critical as the joinery on the surface. We use either metal or wooden supports depending on the table design and buyer request, but the principle remains the same: the support must stabilize the top without locking wood movement.

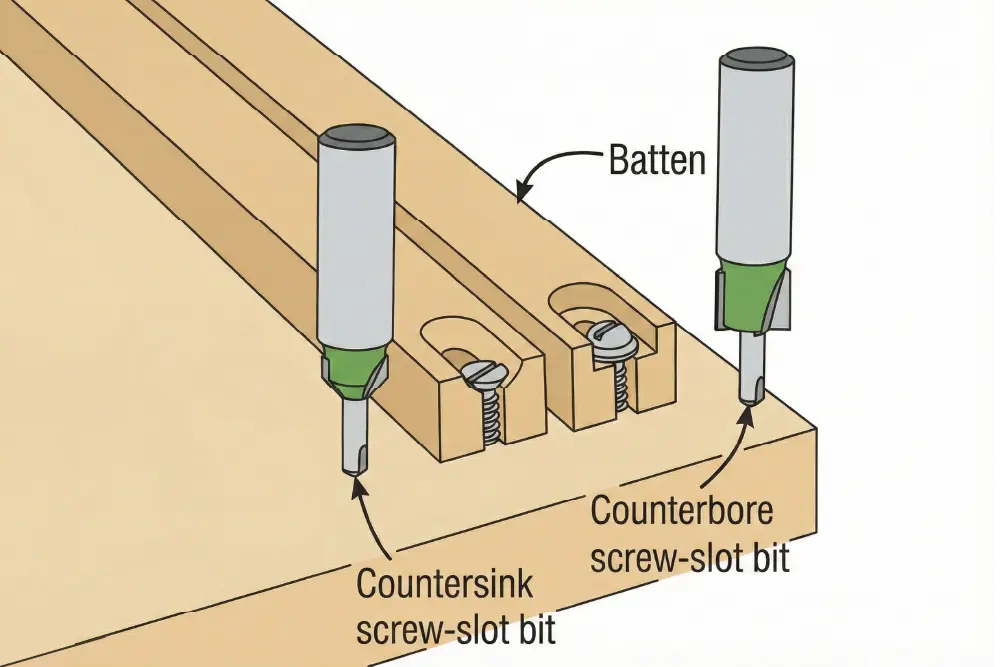

We always use countersunk screw slots when fixing supports to the tabletop. The countersink creates space for the screw to move as the wood expands and contracts. This allows the screw to follow the wood’s movement instead of pulling against it.

When supports are fixed rigidly without movement allowance, stress concentrates around the screw points. From experience, this does not only cause warping; it often leads to cracks at the joint or even splits in the tabletop itself. Proper countersink support construction prevents this pulling effect and significantly reduces the risk of post‑shipment cracking.

Table Leg Construction: Mortise and Tenon Joint

For leg-to-top connections, we rely on mortise and tenon joinery designed for load-bearing furniture because tables carry a continuous load and require joints that stay tight over time. Simple screw connections are not sufficient for this type of stress and often loosen after repeated use.

The performance of mortise and tenon depends heavily on fit. The tenon must be precise, not too loose and not too tight, with enough space for glue to work properly. When needed, we add dowels to lock the tenon and prevent long-term movement.

In practice, leg joints that are forced, over-tight, or improperly glued tend to fail first, leading to wobble and instability. A correctly fitted mortise and tenon transfers load evenly from the tabletop to the legs and keeps the table stable throughout its service life.

Before buyers start evaluating suppliers, it is worth sharing one situation that reflects how these problems usually surface. We have been approached directly by a buyer representative asking why a tabletop cracked after reaching the market.

When we discussed the case from a technical perspective, the root causes came back to moisture content, joinery decisions, and support construction; details that had never been discussed clearly before the order was placed.

How to Evaluate Indonesian Furniture Manufacturers Beyond Product Samples

Before buying Indonesian furniture, especially tables, Its important to evaluate a table supplier. Buyers should look beyond samples and focus on technical understanding, especially when buying Indonesian furniture directly from manufacturers who may prioritize speed or cost over engineering discipline.

Buyers unfamiliar with this risk should understand the broader challenges of buying Indonesian furniture directly from manufacturers. Samples only show appearance; they do not reflect how a table will perform after shipment and daily use.

The fastest way to assess a supplier is by asking direct technical questions and paying attention to how clearly they are answered. Suppliers who understand table engineering can explain their decisions; those who rely on visuals usually cannot.

Key questions buyers should ask:

- What moisture content level do you require for tabletops before production begins? Clear target numbers show process control.

- What joinery system do you use for joining tabletop boards, and why? Look for explanations about movement allowance, not just strength.

- How is the tabletop supported underneath to prevent movement without locking the wood? Rigid fixing is a red flag.

- How are table legs constructed to prevent wobble over time? Answers should explain load transfer and joint behavior.

These questions quickly reveal whether Indonesian furniture suppliers understand how tables behave after shipment. If answers stay focused on price, design, or inspection results, the risk remains high.

Conclusion

Most Indonesian table defects are not caused by bad wood or poor luck. They are the result of early decisions around moisture content, joinery, support construction, and leg structure that are already locked into the product before shipment.

For buyers, the risk is not visible at sampling or inspection. It appears later, when the container is opened, the table is used daily, and end customers start complaining. At that point, the cost is no longer technical; it is commercial and reputational.

Selecting an Indonesian table supplier should therefore be based on technical understanding, production discipline, and consistency, not price or appearance alone. Working with manufacturers who understand table engineering from the inside helps reduce defect risk, protect your brand, and support long-term business growth.

Still Wondering Your Needs for Build Your Collection Line?

Schedule a Consultation and Discuss Your Needs with Us

FAQ: Mindi Wood Furniture Defects

1. Why do defects in mindi wood furniture often appear after shipping, not during inspection?

Most defects appear late because Mindi wood reacts to moisture imbalance and climate change. Furniture can look stable at inspection while internal stress is still present, which only releases after shipping, storage, or adjustment to a new environment.

2. Are mindi wood furniture problems caused by the wood itself?

No. Most problems are not caused by the material, but by improper processing. When drying, joinery, and production standards are rushed or handled generically, defects become predictable outcomes.

3. What is the main manufacturing mistake that causes warping and cracking in mindi furniture?

The most common mistake is poor moisture control. Skipping gradual pre-drying and forcing the wood into kiln drying too quickly creates internal stress that later causes warping, twisting, or cracking.

4. What moisture content is safe for mindi wood furniture?

Mindi wood furniture should be produced with a moisture content below 12%, reached gradually through proper pre-drying and controlled kiln drying. Drying the wood too fast increases the risk of internal stress and delayed defects after delivery.

5. How can buyers reduce risk when sourcing mindi wood furniture from Indonesia?

Buyers should evaluate the supplier’s production system, not just samples or pricing. Asking about drying methods, joinery standards, and bulk consistency controls helps prevent defects after delivery.

Picture Source

- Tongue and Groove Joinery: https://www.woodworkersjournal.com/cutting-tongue-groove-joints-table-saw/

- Counter Sink Joinery: https://www.woodmagazine.com/woodworking-how-to/wood-preparation/dealing-with-wood-movement

Hi, I’m Salman, founder of MPP Furniture, an Indonesian furniture manufacturer serving global retailers and project-based clients.

I began my career in my family’s export-oriented furniture company, gaining hands-on experience in production, construction, finishing, material performance, and product development. With a clear understanding of how international buyers evaluate furniture quality and reliability, I founded MPP Furniture to deliver export-ready products with consistent standards.

Here, I share insights from the perspective of a furniture manufacturer working directly with production teams on the factory floor, focusing on manufacturing and supplier evaluation.

Connect on LinkedIn

0 Comments